Hybrid ceramic ball bearings characteristics of silicon nitride the ceramic balls in hybrid ceramic ball bearings are made of silicon nitride sí3n4.

Hybrid ceramic ball bearings for turbochargers.

Ball bearing systems for turbochargers can utilize ball bearings made entirely of steel or so called hybrid ceramic ball bearings that are constructed from steel races and ceramic balls.

Fuel savings is required to protect the global environment and save energy in automobiles.

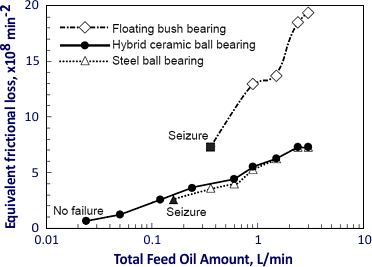

We developed hybrid ceramic ball bearings using silicon nitride ceramic balls for turbochargers which have long life low power loss high seizure resistance and high durability and started mass production from 1998.

The ceramic hybrid ball bearing cartridges are now being rolled out retrospectively throughout our range of performance turbos and by the end of this year most of the turbos currently using the extremely reliable ball bearing cartridges with steel balls will be available using the latest ceramic hybrid ball bearings.

Looking for more information.

The airwerks sx and sx e incorporate serviceable twin hydrodynamic journal bearings with a high pressure ratio compressor stage utilizing extended tip technology and a high efficiency turbine stage.

Hybrid ceramic bearings have traditional 52100 steel or stainless steel rings with ceramic silicon nitride si3n4 balls.

Turbochargers are one of the means to improve the power of automobiles with small displacement engines.

Ceramic bearing balls are commonly made from silicon nitride si 3 n 4.

Ceramic ball bearing turbochargers has been out for a while been recommended for high power and high response.

This is the first adoption of hybrid ceramic ball bearings for passenger car turbochargers in the world.

And there are few turbo companies currently building them.

Turbocharger bearings ceramic turbocharger ball bearings are of the angular contact type.

We have developed hybrid ceramic ball bearings with silicon nitride ceramic balls for turbochargers and are now mass producing these bearings.

Typically these bearings utilise ceramic balls cages anti rotation devices an outer ring a compressor inner ring a turbine inner ring and a series of oil flow control jets or squeeze film dampers.